- Overview

- Inquiry

- Related Products

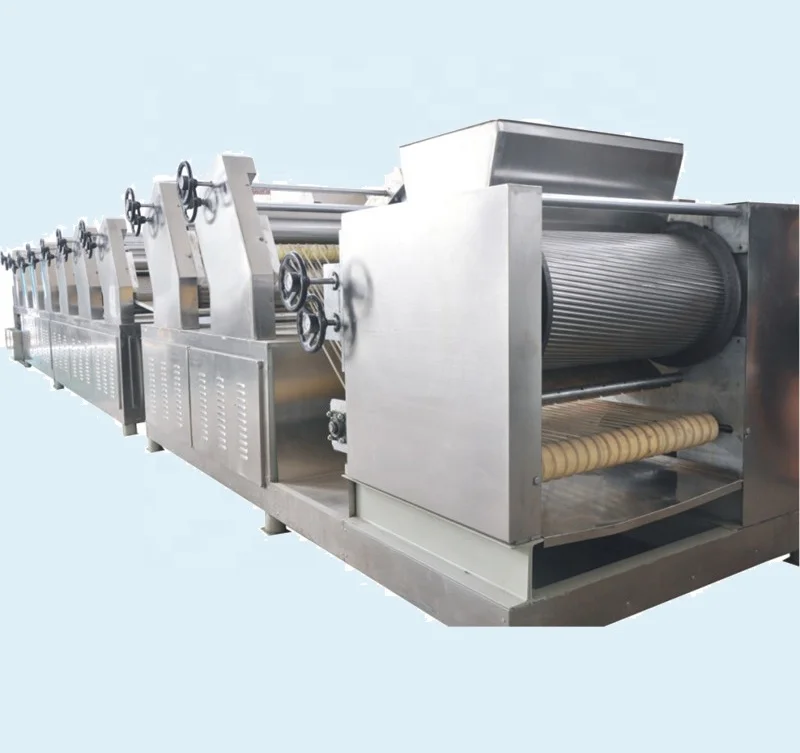

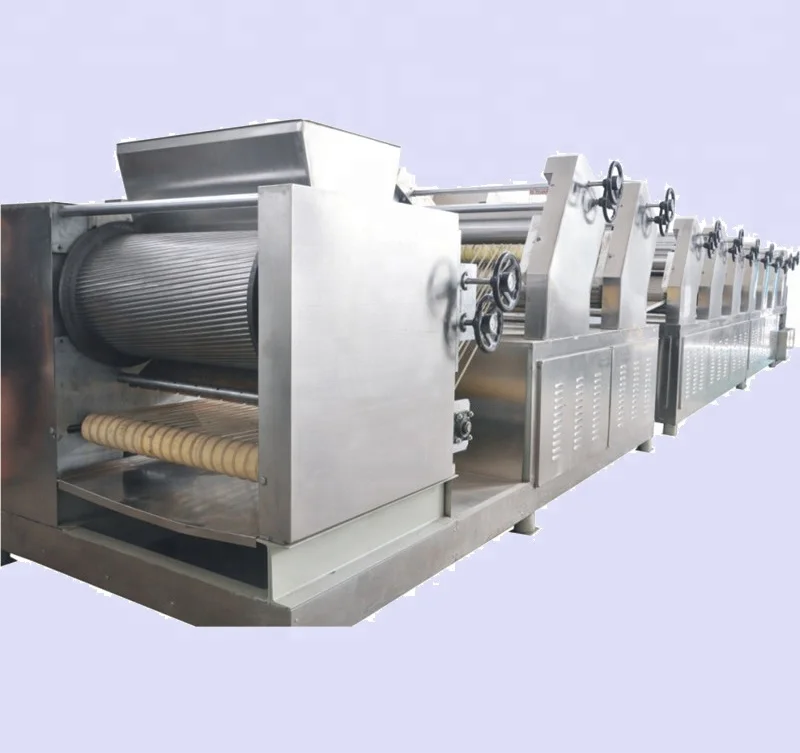

Presenting the Cheap Price the instant noodles production line manufacturing a reasonable and solution efficient your meal production requirements. Our item provides easy and production quick of noodles at an cost unbeatable without the need to sacrifice quality or functionality.

Made out of ease in your mind, the Cheap Price the instant noodles production line is not difficult to work and keep maintaining, insurance firms a user interface user-friendly permits effortless modification linked to the production procedure. Its modular design enables simple expansion and modification as the organization grows, making this a investment versatile will always be the test of times.

The Cheap Price the instant noodles production line is capable of making a number of noodle varieties, including slim noodles, dense noodles, circular and flat noodles, along with egg noodles featuring its high-speed and exact production abilities. It might also create noodles which can be flavored such as chicken, beef, and seafood, to pay attention to various palates and choices.

Our item is sold with advanced level technology and materials which are high-quality ensure its durability, dependability, and persistence in performance. Its tight control over noodle size and texture, along with its high effectiveness in manufacturing, really helps to make sure that you'll regularly deliver quality premium that meet the expectations of your respective clients.

Another function that sets the Cheap Price the instant noodles production line aside from the rivals is its power effectiveness. Our item is done with energy-saving elements in cutting your organization's carbon impact and minimize your power bills. This may make our item a practical and investment sustainable will gain your organization, the surroundings that are environmental along with your important thing.

Cheap Price the instant noodles production line stick noodle steamed making machine

Power:0.75kw, volume:120L/unit,

the surface touched with the water is SS304

2. double- speed flour mixing machine

double- speed flour mixing machine

Motor power 9/11kw,200kg/batch,

door opening by manual, the surface touched with flour is SS304

Motor:4kw,tray size:φ1800mm×410mm the surface touched with flour is SS304

4. Compound- continuous rolling machine

Compound- continuous rolling machine

Roll width:350mm,motor power:5.5kw+5.5kw(frequency conversion timing),

7 pairs of steel roller-cold-hard alloy, frame (two sides)is SS201,the Dia. of the roller is:φ180mm×2,φ240mm×2,φ180 mm×2,φ162mm×1

the surface touched with flour is SS304,aluminum glass door

Specification:750*850*1400mm,six roll of noodle can be put in

6. Dehydration sterilization machine

Dehydration sterilization machine

Main driven 1.5kw(frequency conversion timing),the length of body is 16 meters,

surface touching food is SS 304,

Heating power~20kw

operation adopts frequency conversion timing

|

Serial NO. |

Product name |

Model |

quantity |

|

1 |

alkali mixing and measuring |

YSH10 |

1 unit |

|

2 |

double- speed flour mixing machine |

HMJ200 |

1 unit |

|

3 |

Disk-type feeder |

PS200 |

1 unit |

|

4 |

Compound- continuous rolling machine |

MT7-50 |

1 unit |

|

5 |

belt type cabinet |

SX6 |

2 units |

|

6 |

Dehydration sterilization machine |

TS800 |

1 unit |

|

7 |

electrical control system |

BPT-1 |

1 set |

More capacity for instant noodle machine

( for your reference)

|

OUTPUT |

POWER |

STEAME CONSUMPTION |

SIZE |

WORKSHOP REQUIREMENT |

WORKMAN REQUIRMENT |

|

40,000bags/8h |

42KW |

1000-1200KG/H |

L45m*W5m*H2.5m |

L60m*W6m*H4.5m |

5persons/shift |

|

60,000bags/8h |

56KW |

1200-1400KG/H |

L49m*W5m*H2.5m |

L70m*W6m*H4.5m |

7persons/shift |

|

80,000bags /8h |

68KW |

1300-1500KG/H |

L56m*W5m*H2.5m |

L75m*W6m*H4.5m |

9persons/shift |

|

100,000bags/8h |

80KW |

1400-1600KG/H |

L59m*W5m*H2.5m |

L80m*W6m*H4.5m |

11persons/shift |

|

120,000bags/8h |

83KW |

1600-1800KG/H |

L60m*W6m*H3m |

L80m*W7m*H4.5m |

13persons/shift |

|

160,000bags/8h |

106KW |

1900-2100KG/H |

L85m*W6m*H3m |

L105m*W7m*H4.5m |

15persons/shift |

|

200,000bags/8h |

114KW |

2000-2200KG/H |

L90m*W6m*H3m |

L110m*W7m*H4.5m |

15persons/shift |

Low temperature hanging noodle production line, the device uses frequency control, photoelectric tracking, PLC program control, To achieve a full range of synchronous coordination control. And the surface of the machine using oval-shaped pulp double-axis two-speed technology to add more water, material and moisture more uniform; curing machine using W-type double pot technology; rolling machine with 7-9 pairs of cold alloy roll, Arch dry low-temperature slow drying process, cutting section using pneumatic cutting technology (or automatic hob section technology),Is the ideal domestic production of noodles equipment.

The following is my company's superior products, details please click.

To avoid instant noodle making machine damage from transportation, wood crate is double layered with inner supporting girders and nailed by staggering technique to increase its loading strength.

EN

EN

AR

AR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

AZ

AZ

BN

BN

LO

LO

LA

LA

MN

MN

NE

NE

MY

MY

KK

KK

UZ

UZ