- Overview

- Inquiry

- Related Products

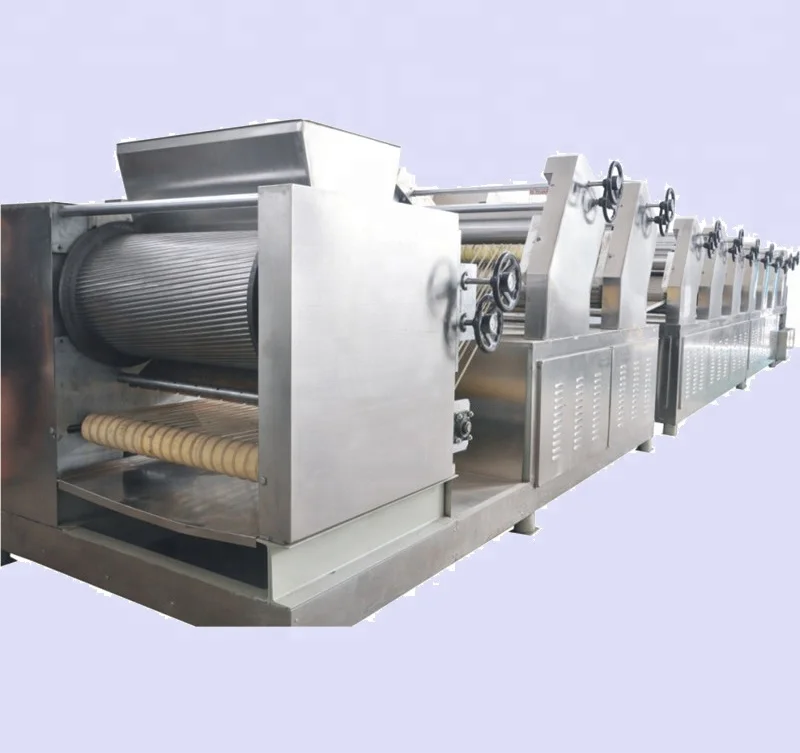

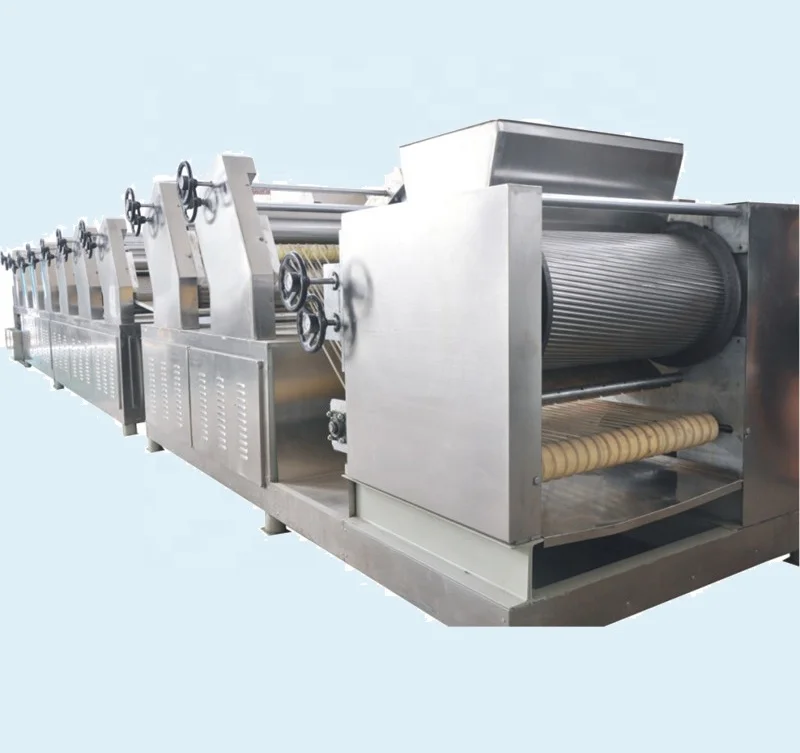

Introducing the Click on Higher Rate Automated Operating Coming from Flour Towards Packaging Indomie Noodle Creating Devices, happily produced due to the brand name G-YOUNG popular. This noodle high-grade gadget was meant towards charm the hectic requirements of meals handling business insurance coverage companies an automation body that assurances benefit efficiency.

This noodle equipment creating carefully crafted possessing a much more outstanding variety innovation that allows it just get flour all-organic alter it right in to noodles, appropriate up the very best product packing treatment without the interruption. Insurance coverage companies a remarkable production capability as much as 300 packages of noodles every minutes, who might be the ideal service for companies that have to create huge quantities of high-quality noodles in just an opportunity short.

The device is created along with high-quality aspects being produced particularly collaborate, providing a reliable satisfaction resilient. These gadgets requires very little driver treatment, creating specific your company runs effectively along with completely procedures that are automated.

Among the primary considerable fantastic aspects of Click on Higher Rate Automated Operating Coming from Flour Towards Packaging Indomie Noodle Creating Devices is its own versatility. Its own fit producing a myriad of noodle ranges, like for example Indomie, ramen, pasta, condition a number of.

The gear's custom-designed command body assurances determination in product high top premium, ensuring every noodle set created fits the market that you require. The apparatus's modular style enables quick modifications, making it easy change in one solitary range noodle another with no downtime.

The safety of drivers is very most crucial, G-YOUNG recognizes that totally. The noodle producing devices is developed along with security functions that increase the safety of drivers throughout treatment. Additionally, the dust progressed body guarantees a tidy workplace, suitable much healthier procedures.

High Speed Automatic Running From Flour To Packing Indomie Noodle Making Equipment

Product Description

Roll width:350mm capacity: 1.5T/8h

Mainconfiguration

|

Serial NO. |

Product name |

Model |

quantity |

Remark |

|

1 |

alkali mixing and measuring |

YSH10 |

1 unit |

Power:0.75kw, volume:120L/unit, the surface touched with the water is SS304 |

|

2 |

double- speed flour mixing machine |

HMJ200 |

1 unit |

Motor power 9/11kw,200kg/batch,door opening by manual, the surface touched with flour is SS304 |

|

3 |

Disk-type feeder |

PS200 |

1 unit |

Motor:4kw,tray size:φ1800mm×410mm the surface touched with flour is SS304 |

|

4 |

Compound- continuous rolling machine |

MT7-50 |

1 unit |

Roll width:350mm,motor power:5.5kw+5.5kw(frequency conversion timing),7 pairs of steel roller-cold-hard alloy, frame (two sides)is SS201,the Dia. of the roller is:φ180mm×2,φ240mm×2,φ180 mm×2,φ162mm×1 |

|

5 |

belt type cabinet |

SX6 |

2 units |

the surface touched with flour is SS304,aluminum glass door Specification:750*850*1400mm,six roll of noodle can be put in |

|

6 |

Dehydration sterilization machine |

TS800 |

1 unit |

Main driven 1.5kw(frequency conversion timing),the length of body is 16 meters,surface touching food is SS 304, Heating power~20kw, fan0.55kw×6 |

|

7 |

electrical control system |

BPT-1 |

1 set |

operation adopts frequency conversion timing |

Feature

The production line of fried instant noodle produced by our company boast many technologies and advanced technologies . The whole production, with unique production technology, novel design, safe reliability, beautiful appearance and high auto-immunization, is a comparatively advanced environmental apparatus of instant noodles in China.

1.1.1Advanced technologies and high automation

The closed-loop speed control system, consisting of speed feedback control and photoelectric tracking, is designed to perform synchronous control on the whole production line, and it is featured of easy adjustment and high precision synchronization.

It takes the programmable logic controller (PLC) as the process center, and perform automatic control on the process, and the motors on most single machines adopt frequency speed control.

1.1.2High quality, efficiency and sound shaping

The noodle cake has regular shape, uniform corrugation, well-proportioned color and high quality.

It has stable performances and high efficiency and easy to operate.

1.1.3Advanced process

The flour mixing machine is designed with double shafts and double speeds for optimal dough mixing effect.

The calendar ratio of rolling machine is designed logically, and the clearance between rollers is easy to change.

Varieties of series of production equipment

200 thousand pieces / 8H fried noodle production line

160 thousand pieces / 8H fried noodle production line

120 thousand pieces / 8H fried noodle production line

100 thousand pieces / 8H fried noodle production line

80 thousand pieces / 8H fried noodle production line

60 thousand pieces / 8H fried noodle production line

40thousand pieces / 8H fried noodle production line

10thousand pieces / 8H fried noodle production line

main character

1 .High automation ,PLC controlled

2. High efficiency ,saving man power

3.Capacity: from2.5-20tons per 8hours(based wheat flour consumption)

4.Made Material :main used SSL

5.Easy operation, repair and maintenance

6.fully automaticnoodle production line

7.Theweight and size for each noodle cake can be customized

Flow Chart

Flour storage→Flour lifting→Flour measuring→Flour mixing→Alkali mixing and measuring→Ripening→Compound pressing→Curing→Continuous pressing→Shaping→Steaming→Cutting→Dividing→Frying

Why choose us ?

* View our Factory.

* Training how to install the machine,training how to use the machine.

* Engineers available to service machinery overseas.

*First installation can be done by engineer.

*Training workersin customer’s factory.

*Fully equippedtest workplace

*professionalR&D teams

EN

EN

AR

AR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

AZ

AZ

BN

BN

LO

LO

LA

LA

MN

MN

NE

NE

MY

MY

KK

KK

UZ

UZ